The only technology built on both essential pillars to efficiently manage friction and guarantee results: composite materials and application devices. Materials with over 40% of solid particles guarantee unmatched results: up to 99,9% squealing and up to 70% rail/wheel wear reduction. The formulas of the materials have not changed since the beginnings – because they deliver results. The application devices however have been evolving for over two decades and are now protected with 30 patents.

Headquarters

PRODUCT CATEGORIES

Infrastructure

- Infrastructure systems and components

Maintenance Services

- Infrastructure/track maintenance

- Rolling Stock and Vehicle Component Maintenance

- Supply of maintenance equipment

Rolling Stock

- Locomotives

- Long distance and regional passengers trains (up to 250km/H)

- Urban and suburban trains (including tamways, LRT, metros)

EUROPEAN FACILITIES

GLOBAL PRESENCE

FEATURED PRODUCTS

“i-ROCK spray” – on-board friction management device

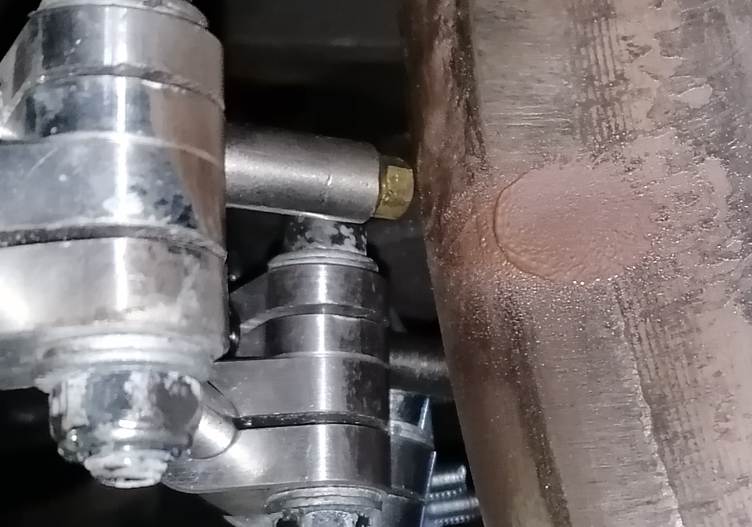

i-ROCK applies composite materials with very high content of solid particles. Arguably the most energy efficient device with very low consumption of compressed air. In combination with proprietary Composite Hardly-Fluid Compounds (CHFC) all contact parts are addressed – just one material to manage all friction. Technologically lowest possible dripping and soiling of the vehicles when proprietary Composite Hardly-Fluid Compounds (CHFC) are used.

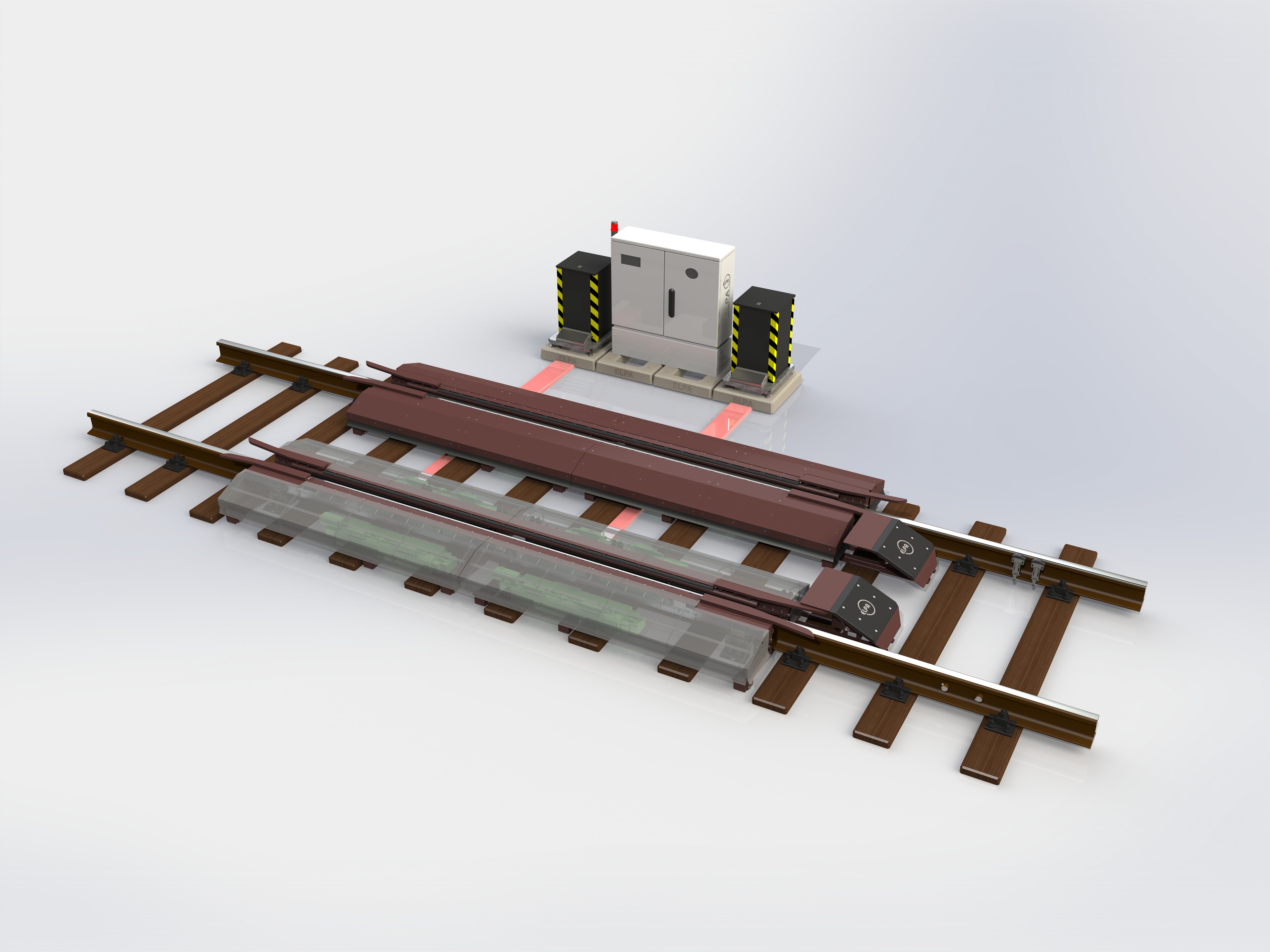

CL-E1 - a trackside friction management device

CL-E1 applies composite materials with very high content of solid particles. Modular system allows high flexibility at the installation on grooved or Vignole rails. Application via dosing blades or bore holes (patented for Vignole rail). Refilling is only required 2-3 times a year due to very low consumption when combined with proprietary Composite Hardly-Fluid Compounds (CHFC). Energy sources: grid or solar. A special solution LIMbo only uses kinetic energy of the wheels on Vignole rails for the operation including mixing in the tank.

Bremex Annsys® – system for reduction of hump yard retarders’ noise & wear

Bremex Annsys® is an award-winning globally unique system for elimination of high frequency noise emitted by the braking shoes on hump yards. It practically eliminates noise as it is reduced by up to 30 dBA or 99,9%. Wear of braking shoes can be reduced by up to eight times. Because Composite Hardly-Fluid Compound is transferred to the entire marshalling yard by the wheels also significant reduction of wear is generated on switch points, counter rails etc. Savings can amount to several 100s of 1000s of euros annually.

“DPA-tram Airless” – on-board solution for tramways

DPA-tram Airless is an on-board friction management device that works without compressed air. It can apply composite materials with very high content of solid particles and addresses all parts of the wheel-rail interface: wheel tread, wheel flank and wheel flange. Technologically lowest possible dripping and soiling of the vehicles when proprietary Composite Hardly-Fluid Compounds (CHFC) are used.