Lucchini RS is an international Group, specialised in the design and production of high-tech steel products, provides all type of wheels, tyres, axles and wheelsets (completed of axle boxes, bearings, brake discs and drive units). The company offers a complete supply to the customer, giving also full support during all stages of maintenance. Thanks to the R&D department, the company can satisfy the needs of railway sector with a wide range of solutions for all applications.

Headquarters

PRODUCT CATEGORIES

Maintenance Services

- Rolling Stock and Vehicle Component Maintenance

- Supply of maintenance equipment

Rolling Stock

- Freight wagons

- High Speed trains (over than 250km/H)

- Locomotives

- Long distance and regional passengers trains (up to 250km/H)

- Other (including services, design, consultancy, certification etc.)

- Special Vehicles for infrastructure maintenance

- Urban and suburban trains (including tamways, LRT, metros)

EUROPEAN FACILITIES

GLOBAL PRESENCE

FEATURED PRODUCTS

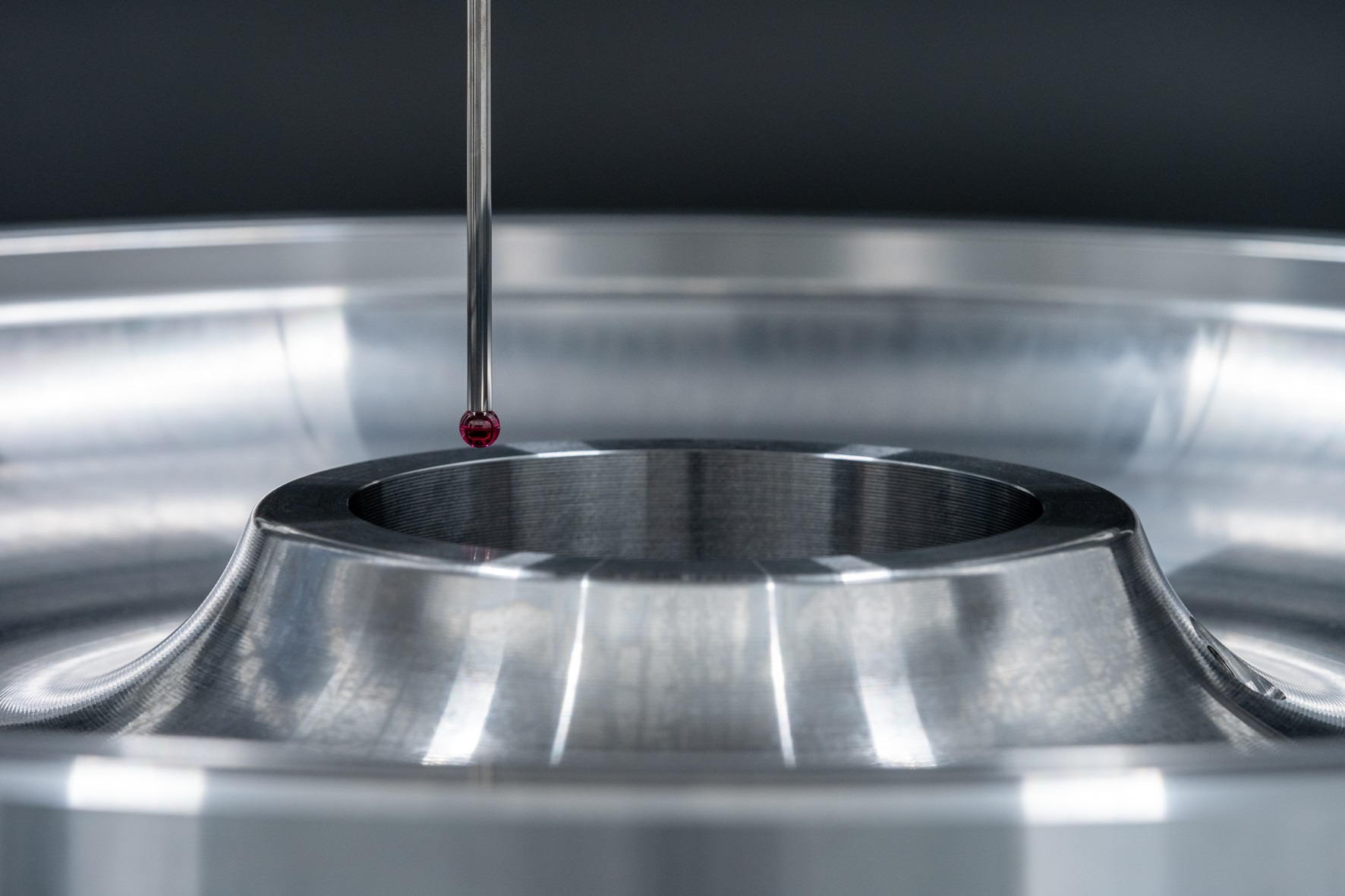

Innovative Steel Grades

Lucchini RS has a dedicated team of metallurgists and engineers that designs and develops advanced steel grades, continuously upgrading their current properties to improve wheels performance. LRS patented special steel grades are suitable to meet different railway application in different and extreme environments: UPLOS®, SUPERLOS®, ARCTICLOS®, SANDLOS®, HYPERLOS®. The finished wheels, axles, and wheelsets are then tested in an independent Lab to prove their superior safety and total in-service life and put reduced wear and rolling contact fatigue in concrete numbers.

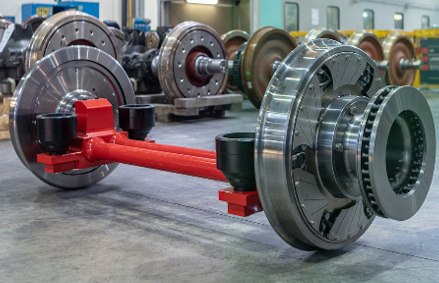

LimoSet®

LimoSet ® innovative portal axle design for low floor LRVs has addressed two distinct objectives: reduction of the Total Life Cycle Cost of the wheelset and introduction of modularity concept. Designed for urban application, it is lighter than the existing solutions. The Total Life Cycle Cost is reduced by 15-20%, while modularity grants easy assembly, disassembly and inspection and lower maintenance costs for the operators.

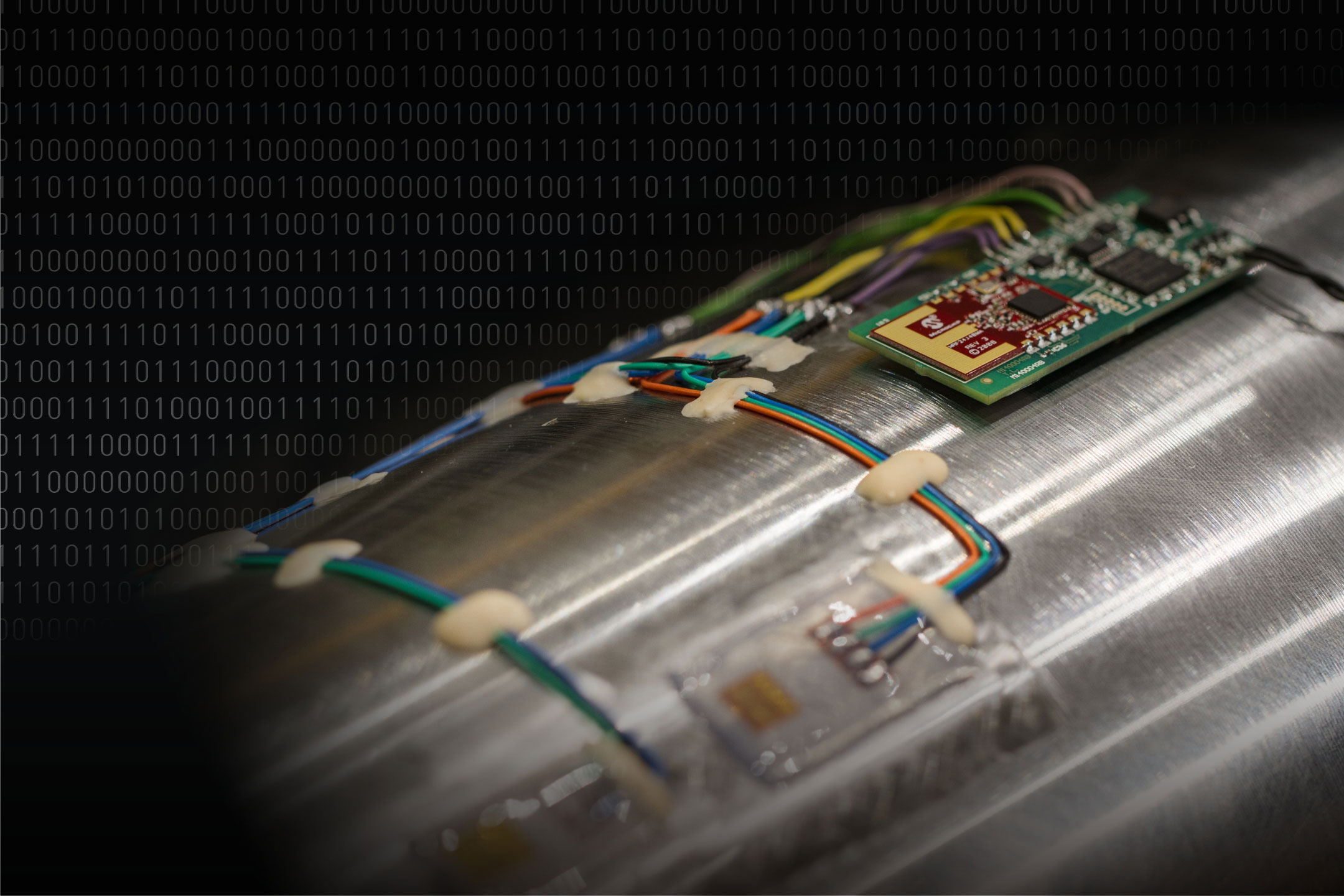

Smartset®

It is an innovative patented solution aimed at optimizing train inspection intervals, increasing vehicle availability and reducing wheelset LCC through a constant, in service, monitoring of axles bending and torsional load spectra. Sensors are imbedded in the axle, under a thick anti-impact coating; collected data are periodically transmitted to a remote server which analyze the actual forces acting on the wheelsets in order to optimize NDT inspection intervals reducing maintenance costs.

Sura®

Thermostable (i.e. “low-stress”) wheels have been designed for all tread-braked applications. Their service-proven deep-shape wheel web design significantly diminishes excessive strains and internal stresses caused by thermal loads. SURA® solutions can be easily adapted for different applications and design scenarios, with no or little impact on the technical homologation process.

Syope®

Lucchini RS Group has developed a number of solutions reducing noise caused by railway wheel operations.A significant reduction of the vibration (and thus also noise) of wheels in operation is achieved through the combination of SYOPE® technology and STARDAMP (TWINS algorithm based software).